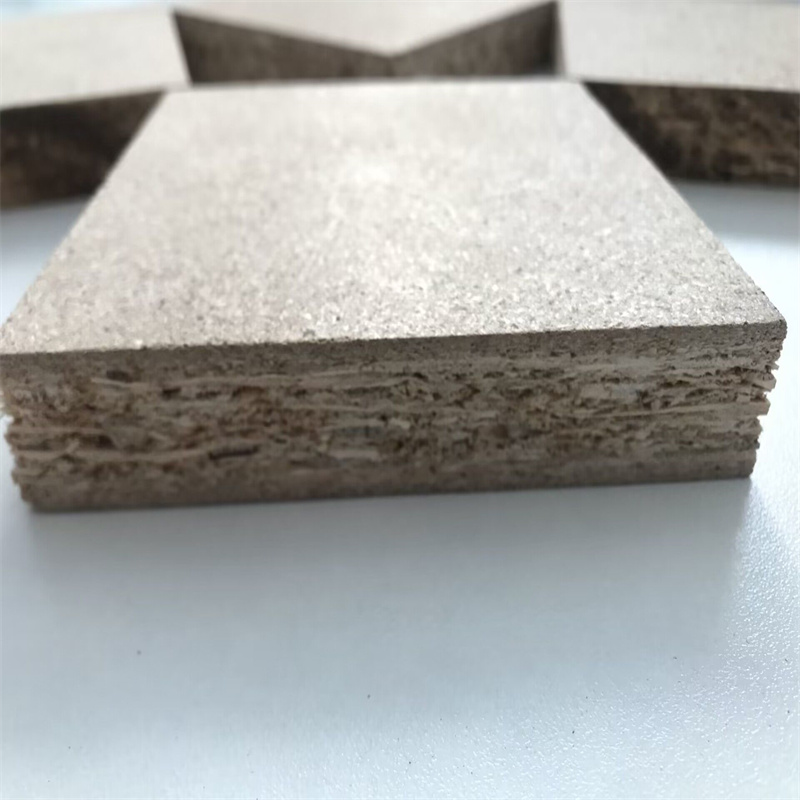

Factory Price Chipboard

Particle board has a uniform structure and good processing performance, it can be processed into large-format boards according to different requirements. It is a good raw material for making furniture of different specifications and styles. Finished particle board does not need to be dried again, so it can be used directly, and it also has good performance in sound absorption and sound insulation.

Particle board is also referred to as chipboard or flakeboard, it's a form of wood-primarily based panel made of timber or different lignocellulosic materials and stuck under warmth and strain after applying adhesive. It's especially used in fixtures manufacturing and creation company, further to teach and car carriage production.

Application Scenarios

1. Furniture

It can be used to make door frame,sofa,curtain box,radiator,floorand floor base material,bed,bookcase,desk,display case ans other furniture bearing structural parts,as well as ship,train manufacturing materials.

2. Structural

Mainly include wooden structure building inside and outside wallboard,floor,big span beam,wall and roof, and building with lining board,indoor panel,heat insulation board,sound-absorbing board,ceiling,wallboard,building template.

3. Packing

It can be recycled,utilization rate of more than 95%,the size can be customized , no fumigation,export inspection exemption,by the World Packaging Association positioning”class 1 exposure’ packaging materials,OSB packing boxes than plywood packing boxes to withstand higher pressure.