Quality MDF for Wall Penel

Medium density fiberboard (MDF) is made of small-diameter logs, harvesting, processing residues, and non-woody plant fiber raw materials. After slicing, cooking, fiber separation, and drying, urea-formaldehyde resin or other applicable adhesives are applied, and then hot-pressed. A kind of man-made board. Its density is generally in the range of 500-880 kg/m3, and its thickness is generally 1-30 mm.

National Standard for Medium Density Fiberboard

Medium density fiberboard is a kind of man-made board with a density of about 0.5-0.88gcm3 after processing selected wood raw materials into fibers, adding urea-formaldehyde resin and other additives, and making it through a special process. The technical standard parameters of domestic first-class medium density fiberboard are as follows: (1) The thickness deviation of the board should be small, generally should be controlled within ± 0.3mm; (2) The water absorption thickness expansion rate is ≤ 12%; (3) The free formaldehyde content does not exceed 70mg /100g; (4) Screw holding force: vertical plate surface ≥ 1150N, parallel plate surface ≥ 660N; (5) plate static bending strength ≥ 17.2MPa;

Medium density fiberboard production process

Medium density fiberboard production process 1. When producing medium and thick boards, logs are not required to be stripped, but the volume fraction of bark is allowed to be less than 8%. The log loader puts small-diameter wood, branch wood and other wood materials on the wood storage platform, and sends them to the chipper through the belt conveyor. A metal detector is installed in front of the chipper to prevent wood with metal from entering the chipper. The wood entering the chipper is cut into standard wood chips, and sent to the wood chip storage warehouse for storage through the screw conveyor and bucket elevator. Since soft wood and hard wood should be mixed in proportion, two storage bins are used to store soft wood and hard wood chips respectively. The discharge device at the lower part of the storage bin can control the discharge speed. According to the process ratio, the discharge device controls the discharge volume, so that the soft and hard wood chips are evenly mixed according to the required ratio. The ratio of soft and hard wood chips is 3:7 or 4:6. The pH value of the mixed wood chips should be relatively stable between 5.0---5.5.

Is MDF environmentally friendly?

Density board (medium fiberboard) and particle board (particle board) are the two most commonly used materials for modern furniture. From the perspective of environmental protection, the quality of products of major brands can be guaranteed. The adhesive (glue) in density board (medium fiberboard) and particle board (particle board) pollutes the environment. Small factories generally use relatively poor (low cost) adhesives, which contain relatively high formaldehyde and benzene content, which will Long-term persistent air pollution to the room. Manufacturers of big brands generally pay more attention to the quality of adhesives, the content of formaldehyde and benzene in them will be controlled at a relatively low level, and the room is often ventilated, which generally has little impact on the human body.

Xinhua Wood Factory Appearance

Xinhua Wood Machinery

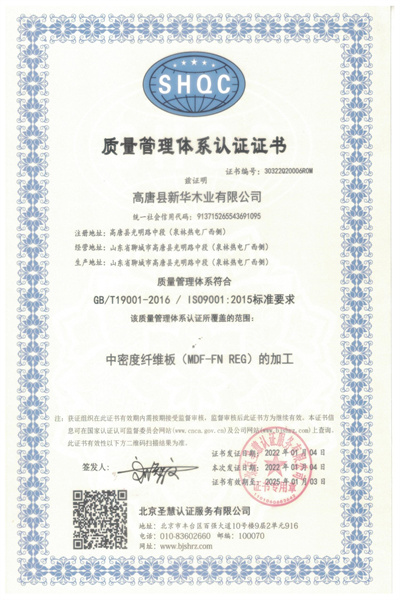

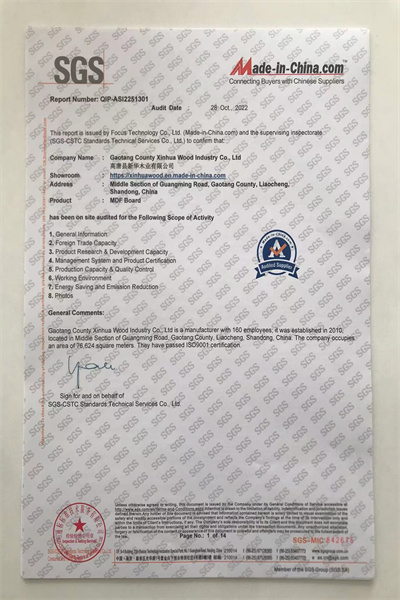

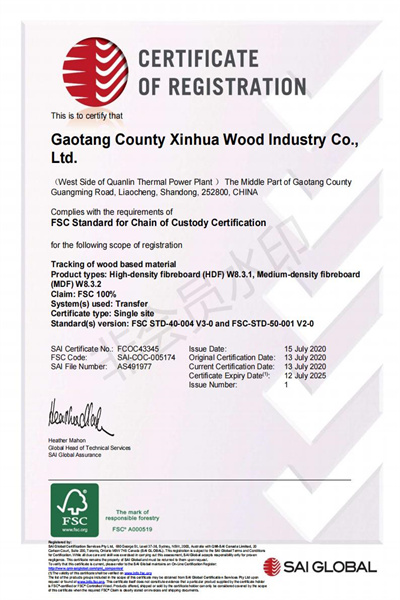

Xinhua Wood Quality Certificates

Xinhua Wood Introduction

Gaotang County Xinhua Wood Industry Co., Ltd. was established in April 2010 with a registered capital of 11 million yuan. It covers an area of about 76,600 square meters, including a construction area of about 22,000 square meters. The company is located in Quanlin Ecological Park of Gaotang County Economic Development Zone, facing 105 National Road in the east, 308 National Road in the south, and Qingyin Expressway in the north. Our company is a professional enterprise integrating production, processing and sales of wood-based panels, with advanced production equipment and strong technical force. The company has more than 200 employees, including more than 50 senior technical managers. The leading products are 0.8-25mm medium and high density fiberboard, particle board .Oriented strand board ,fireproof board, moisture-proof board,etc., with an annual output of 500,000 cubic meters. The products are mainly sold to Hebei, Henan, Jiangsu, Shenyang, Sichuan and other 20 provinces. Our Products have passed ISO9001 quality system certification, FSC forest system certification and SGS international certification. Products are exported to Europe, America, Africa, the Middle East ,South-Asia,and other countries and regions. Xinhua Wood Industry warmly welcome people at home and abroad to visit and negotiate business!