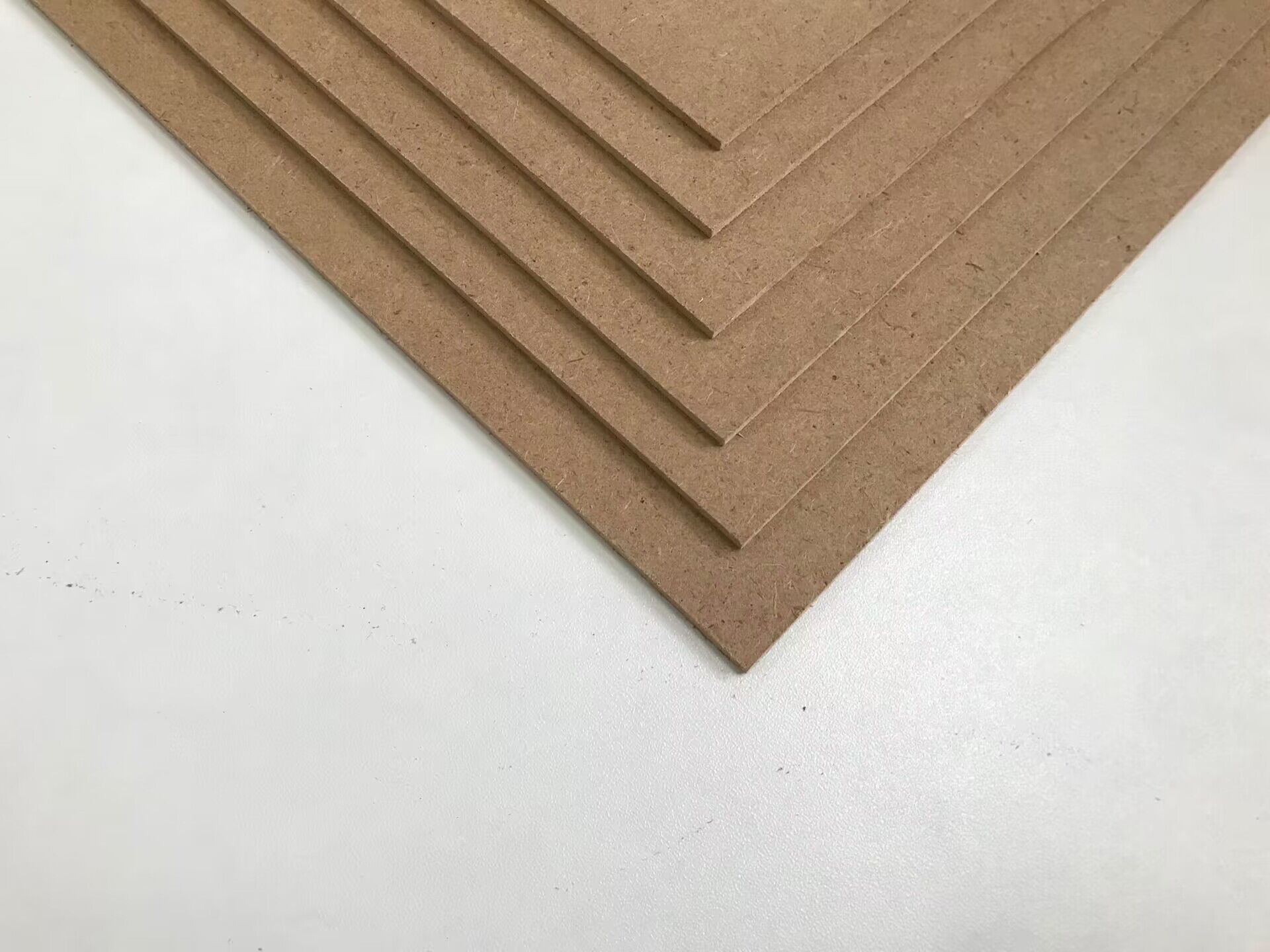

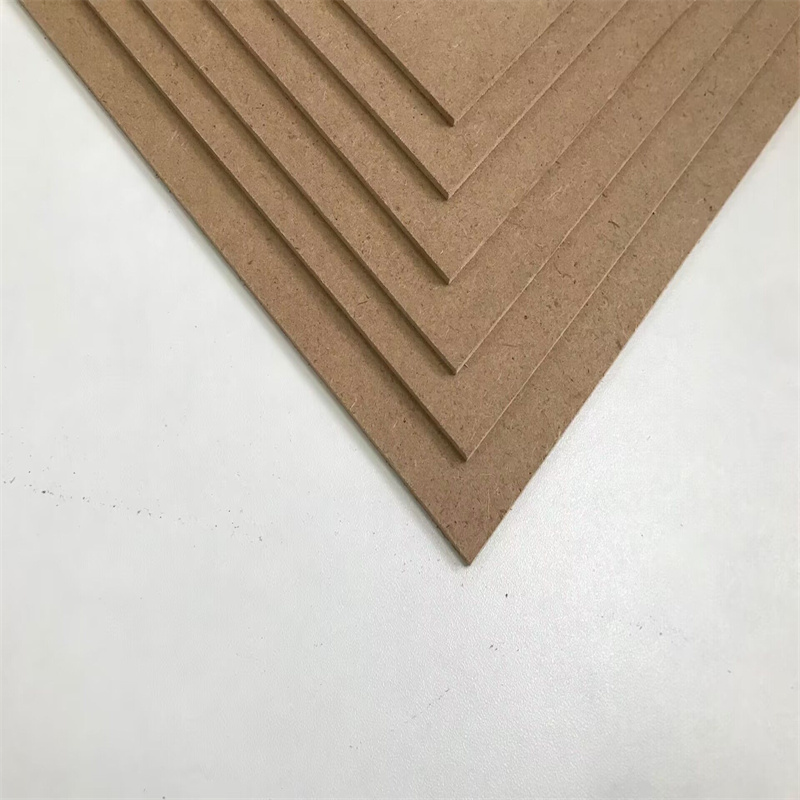

Plain HDF

High Density Fiberboard (HDF) is a kind of board made of wood fiber or other plant fibers, applied with urea formaldehyde grease or other synthetic resins under the condition of heating and pressure.

Product performance

The most advanced flat pressing production line in the world. Therefore, the physical performance is higher and better than that of MDF. Its density is usually above 800kg/M3. The high-density fiberboard produced has reached 930kg/M3, which has reached the advanced level of similar products in Europe and America.

The board surface texture is fine and smooth. When the ambient temperature and humidity change, the size stability is good, and the surface decoration treatment is easy.

The internal organizational structure is fine, especially with dense edges, which can be processed into various special-shaped edges, and it is not necessary to directly paint the edges, so that a better modeling effect can be achieved.

The organizational structure is uniform and the inside and outside are consistent, so the surface can be carved and processed into decorative lines of various sections, which is suitable for replacing natural wood as structural materials.

Usage

High density fiberboard, with its excellent physical properties, is compatible with all the advantages of MDF. It is widely used in indoor and outdoor decoration, office, high-end furniture, audio, and interior decoration of premium cars. It can also be used as the production materials of anti-static floors, wall panels, anti-theft doors, wallboards, partitions, etc. in computer rooms. It is also a good material for packaging. In recent years, it has replaced high-grade hardwood and directly processed it into composite flooring, laminate flooring, etc., which has been widely used in interior decoration. Its smooth surface, solid texture, and ultra long service life have won praise from users.