Good Price MDF for Furniture

The main component of medium density fiberboard is wood or plant fiber. Of course, these materials need to be mechanically separated and chemically treated to make fiberboard, and must be mixed with adhesives and waterproofing agents. It is a widely used man-made panel. Medium density fiberboard is not only more uniform in structure than natural wood, but also can avoid problems such as decay and moth. It has small expansion and shrinkage and is easy to process, which makes the application of medium density fiberboard more extensive.

The Difference Between Plywood and MDF

Wood fibers, resins or glues are used to make MDF. These bond together under pressure and heat to form a cardboard. Plywood is made by gluing thin hardwoods between pieces of wood.

Plywood is made of solid wood while MDF is made of wood fibers. In manufacturing, there is some waste in plywood production, whereas there is no waste in MDF production.

When comparing the two, it can be seen that plywood has attractive grains or knots. However, these particles or nodules are not visible in MDF.

Furniture can easily be made from MDF instead of plywood. MDF can be easily cut and drilled without damaging the surface. On the other hand, more care needs to be taken when cutting or drilling plywood because it has grains or knots.

It is very easy to join MDF pieces with dowels and traditional joints. Additionally, veneers, varnishes, laminates, water-based paints and paints work well with MDF. These will not work on plywood.

Plywood is superior to MDF when comparing strength. Manufacturers produce plywood of varying strengths and simply add more veneer between the pieces. Plywood is better than MDF for both indoor and outdoor use and is also waterproof. Furniture made of plywood is stronger than that of MDF.

Summary:

1. Plywood is made of solid wood while MDF is made of wood fibers.

2. Plywood with attractive grain or knots. However, these particles or nodules are not visible in MDF.

3. There is some waste in the production of plywood, but there is no waste in the production of MDF.

4. MDF can be cut and drilled easily without any damage to the surface. On the other hand, more care needs to be taken when cutting or drilling plywood because it has grains or knots.

5. When comparing strength, plywood is better than MDF.

6. It is easy to join the MDF by pins and traditional joints.

7. Veneers, varnishes, laminates, water-based paints and paints work well with MDF, but do not work well with plywood.

Xinhua Wood Factory Appearance

Xinhua Wood Storage

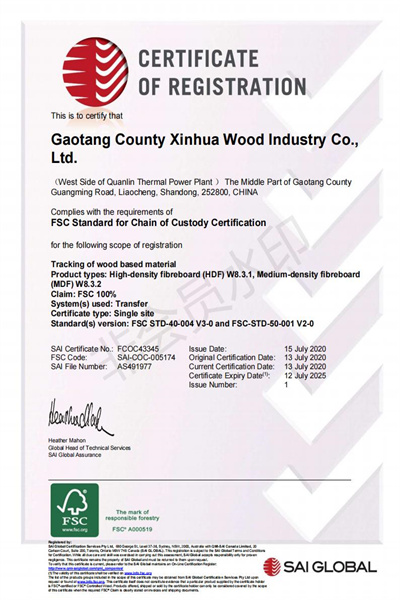

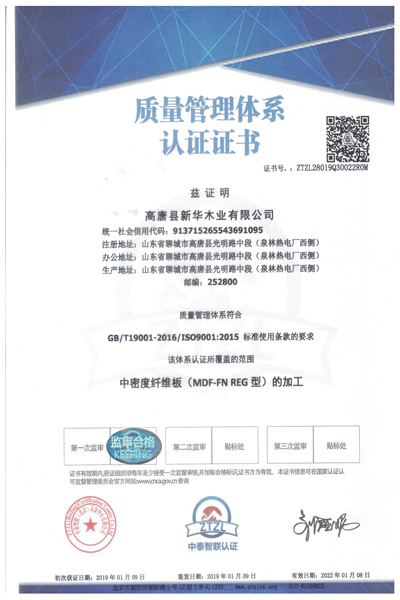

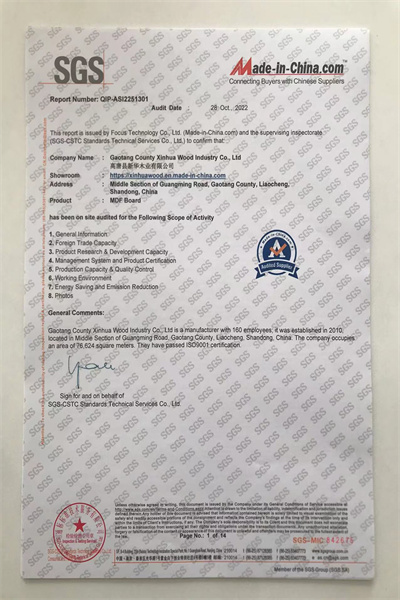

Xinhua Wood Products Certificates

Xinhua Wood Introduction

Gaotang County Xinhua Wood Industry Co., Ltd. was established in April 2010 with a registered capital of 11 million yuan. It covers an area of about 76,600 square meters, including a construction area of about 22,000 square meters. The company is located in Quanlin Ecological Park of Gaotang County Economic Development Zone, facing 105 National Road in the east, 308 National Road in the south, and Qingyin Expressway in the north. Our company is a professional enterprise integrating production, processing and sales of wood-based panels, with advanced production equipment and strong technical force. The company has more than 200 employees, including more than 50 senior technical managers. The leading products are 0.8-25mm medium and high density fiberboard, particle board .Oriented strand board ,fireproof board, moisture-proof board,etc., with an annual output of 500,000 cubic meters. The products are mainly sold to Hebei, Henan, Jiangsu, Shenyang, Sichuan and other 20 provinces. Our Products have passed ISO9001 quality system certification, FSC forest system certification and SGS international certification. Products are exported to Europe, America, Africa, the Middle East ,South-Asia,and other countries and regions. Xinhua Wood Industry warmly welcome people at home and abroad to visit and negotiate business!