Waterproof fiberboard for Kitchen

The main reason why the Moisture-proof MDF can resist moisture is that a waterproofing agent is added during the production process of the wood-based panel to improve the hydrophobicity of the MDF surface, so as to achieve the purpose of moisture resistance.

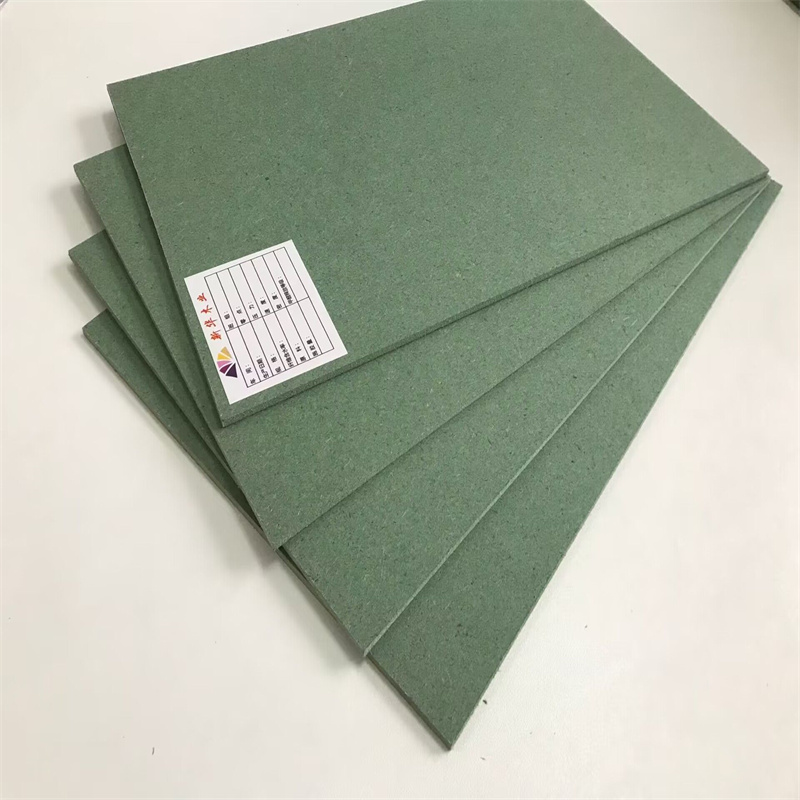

The difference between moisture-proof MDF and conventional MDF is that the color mark is different, and the biggest performance is that it can absorb water and expand the thickness of less than 0.6% after soaking in water for 48 hours. From the surface of the plate, there is basically no change in size and thickness.

Moisture-proof MDF, due to its waterproof properties, is mainly used in relatively humid environments, such as bathrooms, kitchens, etc., and can also be used as a base material for marine decoration materials.

Soak the common substrate and moisture-proof substrate in water at the same time, and the expansion rate of the common plate is significantly higher than that of the moisture-proof plate after two hours of expansion change. The moisture-proof board has good moisture-proof performance and is suitable for making kitchen furniture and bathroom furniture.

Damp-proof board cannot be directly used on furniture, and decorative paper should be pasted on the surface. The normal practice is to soak the decorative paper in melamine solution, and then press it on after hot pressing. Therefore, the moistureproof board we make furniture is generally called melamine moistureproof board.

Melamine is a formaldehyde-free solution, which is environmentally friendly. It will not cause secondary pollution, but will reduce the release of the substrate inside. This treatment method has been recognized by everyone, and most of them are doing so. However, the treatment of this surface is also good or bad, because the price of melamine solution is about 10 times that of other adhesives. Many people mix formaldehyde glue into the solution, which is not very environmentally friendly. So the board is also divided into full-trimer and semi-trimer boards. This non-professional person is hard to recognize, mainly because the surface is not transparent (new, don't look at the old). There is also the difference between the steel plates of the melamine veneer press, which can make the effect of the board surface divided into smooth surface, pitted surface (coarse hemp, fine hemp and velvet hemp), and relief surface (large relief and small relief). The pockmarked surface and embossed surface are 2-3 yuan more expensive than the smooth surface, but they are generally used as cabinet doors, and the general cabinet body is still smooth.