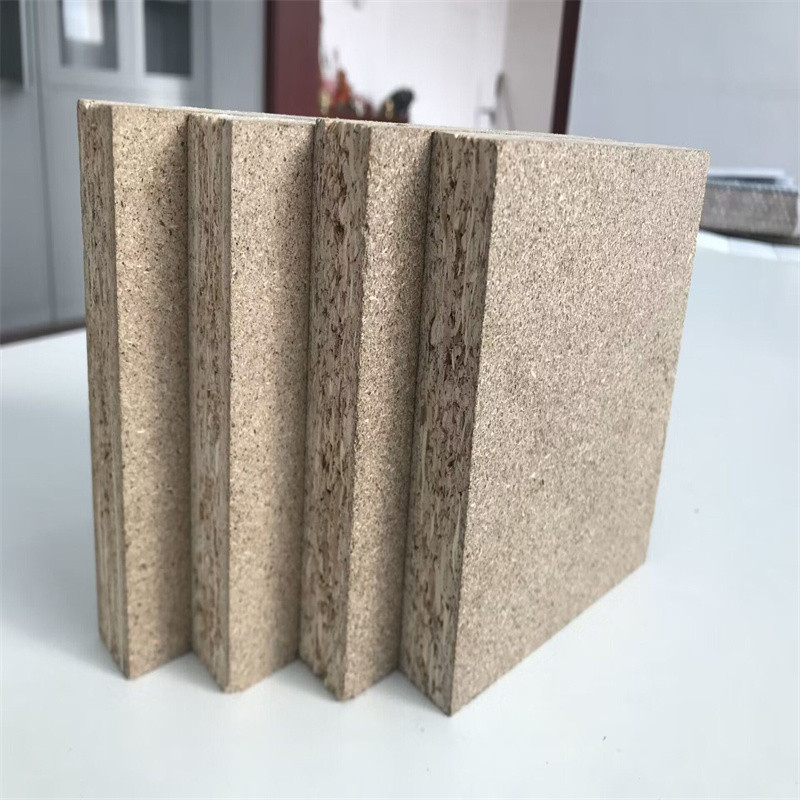

Particle Board for Decoration

Particleboard is also called chipboard. It is a kind of wood-based panel made by cutting various branches and buds, small diameter wood, fast-growing wood, wood chips, etc. into pieces of a certain specification, drying them, mixing them with rubber, hardener, waterproof agent, etc., and pressing them under a certain temperature and pressure.

Particle Board Classification:

According to the use: Class A particle board; Type B particle board

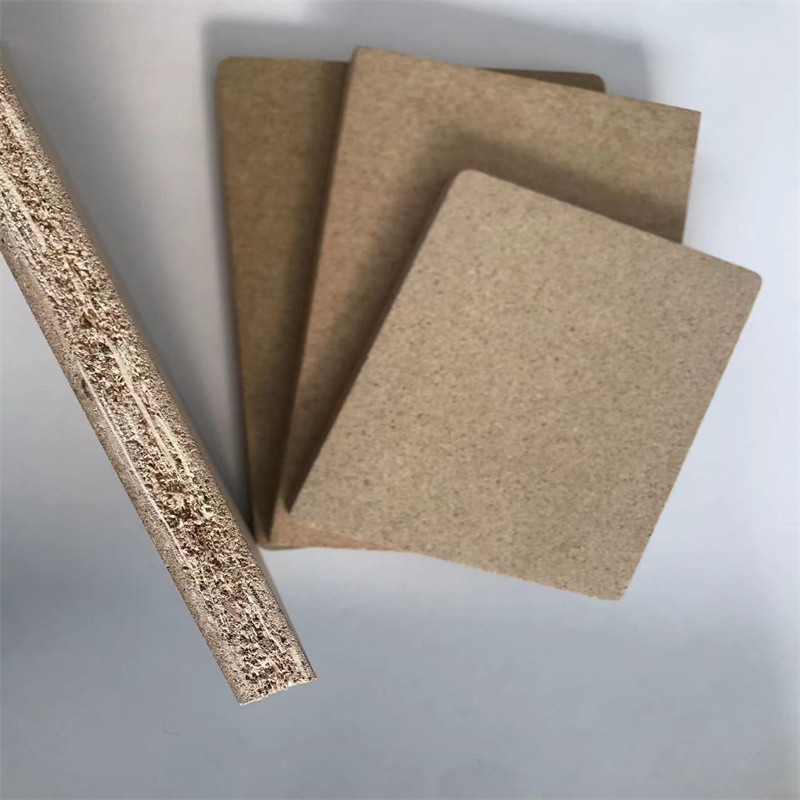

According to the structure of particleboard, it can be divided into: single-layer particleboard; Three layer particle board; Graded structure particle board; Oriented strand board; Waffle particle board; Moulded particleboard.

According to the manufacturing method, it can be divided into: flat pressed particle board; Extrude particle board. According to the raw materials used: wood particle board; Bagasse particleboard; Flax chipboard; Cotton straw particleboard; Bamboo particle board, etc; Cement particle board; Gypsum particleboard.

According to the surface condition:

1. Unfinished particle board: sanded particle board; Unsanded particle board.

2. Decorative particle board: impregnated paper veneer particle board; Decorative laminate veneer particleboard; Veneer veneer particleboard; Surface coated particle board; PVC veneer particleboard, etc.

Chipboards can be divided into low density (0.25 ~ 0.45 g/cm3), medium density (0.45 ~ 0.60 g/cm3) and high density (0.60 ~ 1.3 g/cm3) according to the products, but generally, the production of chipboards is mainly of 0.60 ~ 0.70 g/cm3 density. According to the slab structure, there are three kinds of structures: single layer, three layers (including multiple layers) and gradual change. Indoor water resistance and outdoor water resistance are classified according to water resistance.

According to the arrangement of shavings in the slab, there are two types: directional type and random type. In addition, there are all kinds of particle boards made of non wood materials, such as cotton straw, hemp straw, bagasse, rice husk, and cement wood wool board, cement particle board, etc. made of inorganic adhesive materials. There are many specifications of particle board, the thickness varies from 1.6 mm to 75 mm, and the standard thickness is 19 mm.

When evaluating the quality of particleboard, the physical properties often considered include density, moisture content, water absorption, thickness expansion rate, etc., mechanical properties include static bending strength, tensile strength of vertical panel (internal bonding strength), elastic modulus and rigid modulus of nail holding force, etc., and technological properties include machinability, adhesiveness, paint finishing, etc. For special purpose particleboard, electrical, acoustic, thermal, anti-corrosion, fire-retardant and other properties shall be considered according to different uses.