Particle Board for Furniture

Advantages of particle board.

A. Good sound-absorbing and sound-insulating properties; particleboard is heat-insulating and sound-absorbing;

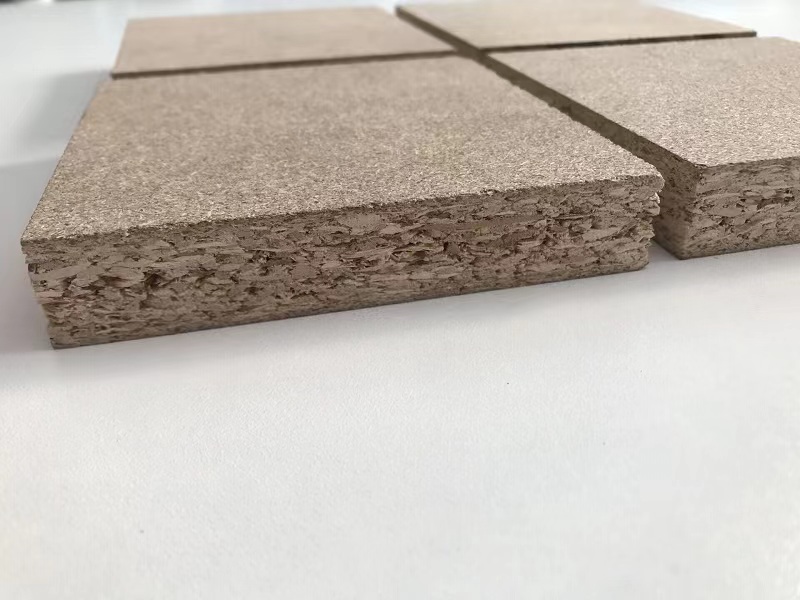

B. The interior is granular with a cross-staggered structure, the performance of each part is basically the same, and the lateral load-bearing capacity is good;

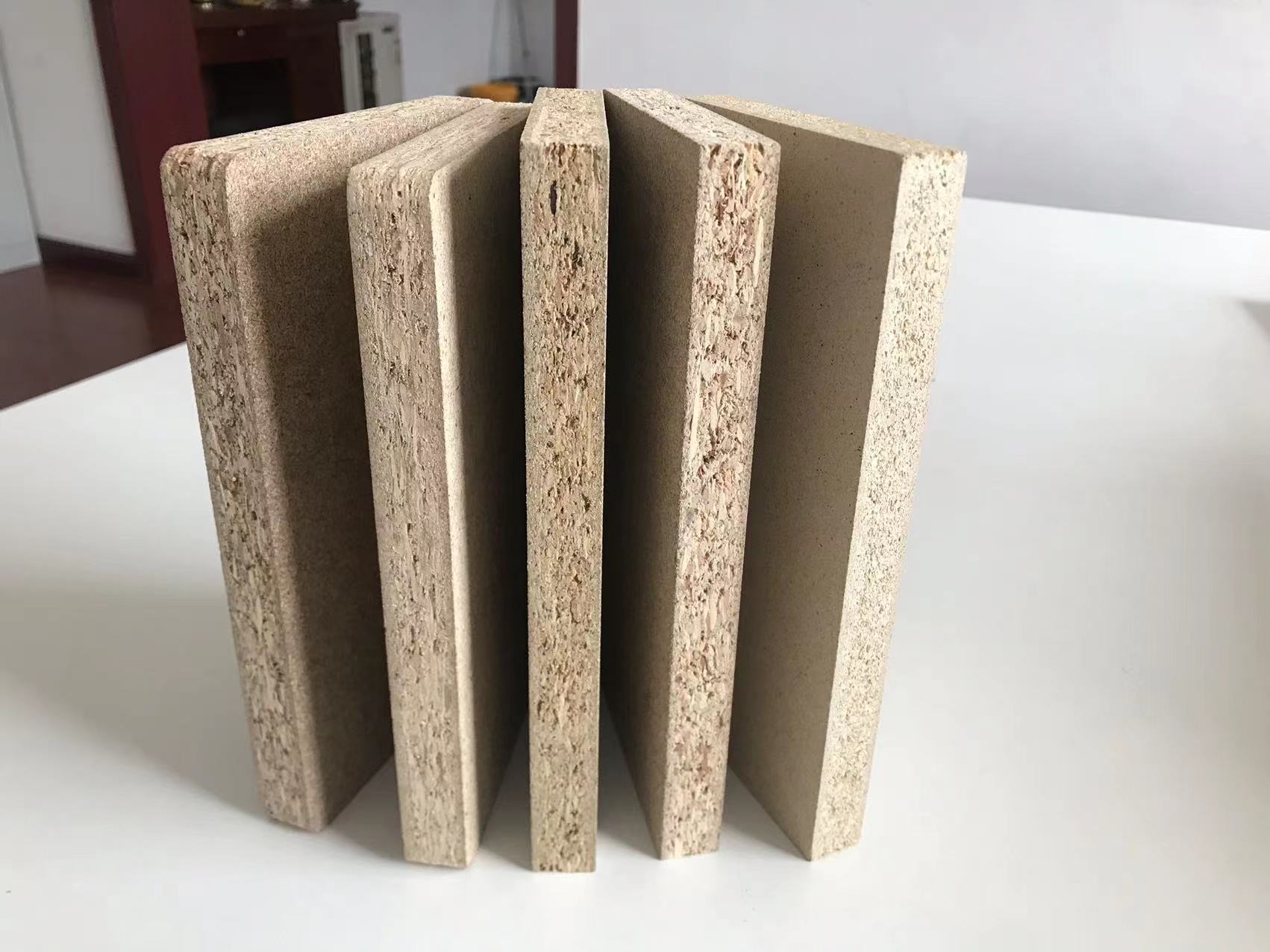

C. Particle board has smooth surface, vivid texture, uniform bulk density, small thickness error, pollution resistance, aging resistance, beautiful appearance, and can be used for various veneers;

D. In the production process of particleboard, the amount of glue used is relatively small, and the environmental protection factor is relatively high.

Particleboard, also known as chipboard, flakeboard, is a wood-based panel that is made of wood or other lignocellulosic materials and glued under heat and pressure after applying an adhesive. It is mainly used in furniture manufacturing and construction industry as well as train and car carriage manufacturing.

Method for judging the quality of particleboard wardrobes

1. From the appearance point of view, look at the size and shape of the sawdust particles in the center of the cross section. The length is generally 5-10MM. If the length is too long, the structure is loose, and if it is too short, the deformation resistance is poor, and the so-called static bending strength does not meet the standard;

2. The moisture resistance of wood-based panels depends on its density and moisture-proof agent. No matter how good the moisture resistance is when soaked in water, moisture resistance refers to moisture resistance, not water resistance, so it must be distinguished in future use. Northern regions, including The moisture content of panels in North China, Northwest, and Northeast China should generally be controlled at 6-8%; in southern regions including coastal areas, the moisture content should be controlled between 8-10%, otherwise the panels are prone to moisture absorption and deformation.

3. In terms of surface evenness and smoothness, generally it has to be polished with about 200# sandpaper when it leaves the factory. Generally, it is better to be finer, but at certain times, such as sticking fireproof boards, etc., it is too fine to be bad. Hang glue.

4. Look at the edge banding of the particleboard. This kind of good particleboard edge banding is particularly important. A good edge banding can not only effectively reduce the release of formaldehyde, but also enhance the moisture-proof performance of the particleboard.