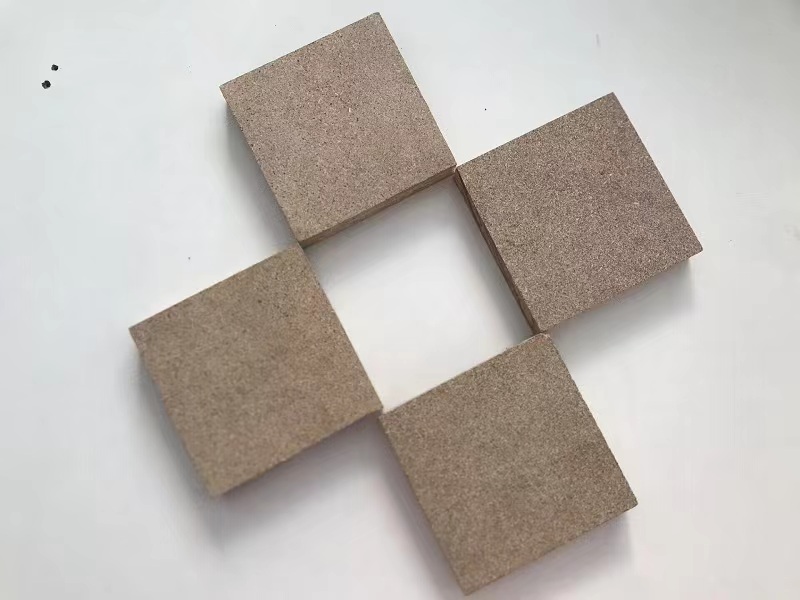

Particle Board for Packing

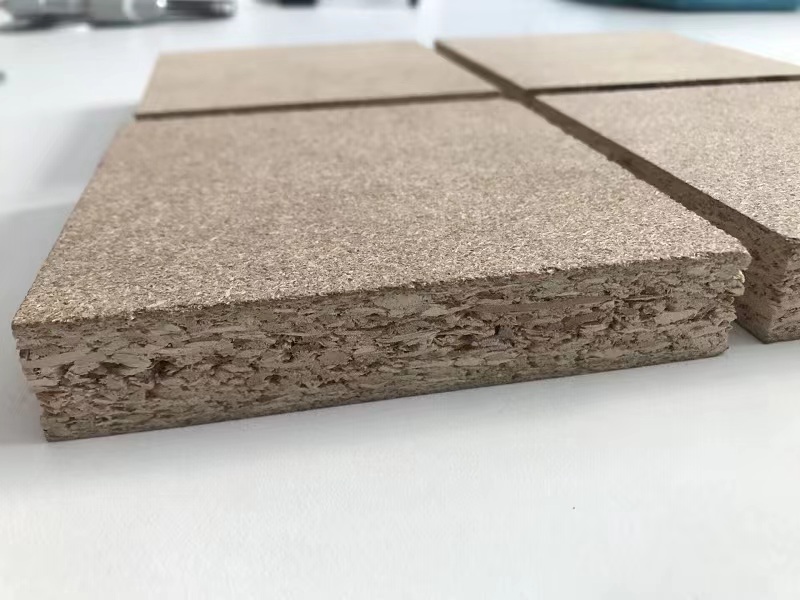

The production methods of particleboard are divided into the flat pressing method of intermittent production, the extrusion method of continuous production and the rolling method according to the different slab forming and hot pressing process equipment. In actual production, the flat pressing method is mainly used. Hot pressing is a key process in the production of particleboard, which is used to solidify the glue in the slab and consolidate the loose slab into a plate of specified thickness after being pressurized.

Advantages:

A. Good sound absorption and sound insulation performance; Thermal insulation and sound absorption of particle board;

B. The interior is a cross scattered granular structure, the performance of each part is basically the same, and the lateral bearing weight is relatively poor;

C. The surface of particle board is flat and can be used for various veneers;

D. In the production process of particle board, the amount of glue used is small, and the environmental protection coefficient is relatively high.

Shortcomings:

A. The interior is of granular structure, which is not easy to be milled;

B. It is easy to cause tooth burst during cutting, so some processes have high requirements for processing equipment; Not suitable for on-site production;

C. The quality of chipboards on the market is uneven, and the environmental protection of low-quality chipboards is very poor. The formaldehyde content exceeds the standard seriously. However, with the national attention to environmental protection, the environmental protection of high-quality chipboards has been guaranteed.