High-strength Particle Board for Furniture

High-strength particleboard was first proposed in 2016 and is a new type of particleboard product. Like ordinary particleboard, it has a three-layer structure. In the core layer, large shavings are processed by the two-stage shaving preparation technology, which changes the shape and paving method of the shavings in the core layer, and then uses MDI glue with high bonding strength for gluing. The high-strength particleboard produced in this way is lightweight, high-strength, and its mechanical properties can meet the requirements of national standards. Moreover, the amount of formaldehyde released is low, which meets the requirements of the national green environmental protection.

What are the characteristics of high-strength particleboard?

The high-strength particleboard adopts the two-stage chipping technology combining the drum chipper and the shaving chipper. The size of the shavings produced by this technology is rich, and it is very easy to change the length of the wood chips. It can effectively use small-diameter materials and save wood resources. The core layer of the board adopts long irregular shavings, which changes the geometric shape of the core shavings of the original particleboard, and uses fine shavings for the surface layer to form a three-layer structure process of surface layer, core layer and surface layer. The density of high-strength particleboard is at least 10% lower than that of ordinary particleboard, and its static bending strength is at least 20% higher than that of furniture-type particleboard. It is a well-deserved "lightweight and high-strength" board. Irregular long shavings can significantly increase the bonding strength in the core layer of the board, the screw force is also significantly improved, and the dimensional stability is better.

High-strength particleboard vs ordinary particleboard

In the production process, the high-strength particleboard adopts the same three-layer particle structure as the ordinary particleboard, and the biggest difference lies in the length and shape of the core particle and the paving method. The length of shavings in the core layer of high-strength particleboard is more than 50mm, while the length of shavings in the core layer of ordinary particleboard is only 10-25mm. The shavings of the core layer of high-strength particleboard are irregular in shape and have better bonding force, while the shavings of ordinary particleboard are regular rectangles. In terms of adhesives, high-strength particleboard uses MDI glue with high bonding strength, and ordinary particleboard uses urea-formaldehyde glue, and high-strength particleboard has higher bonding strength.

High-strength particleboard has the characteristics of light weight and high strength, which can well meet the lack of strength of furniture-type particleboard in cabinet panels and door panels. It adopts a new core particle shape and paving method, which not only has better performance than ordinary particleboard, but also reduces production costs and saves energy.

Xinhua Wood Company show

Xinhua Wood Mahinery

Xinhua Wood Storage

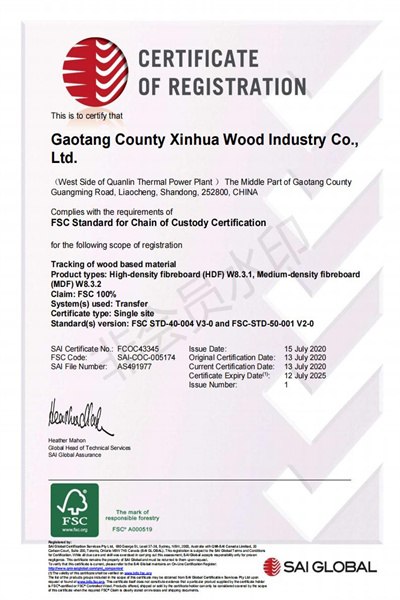

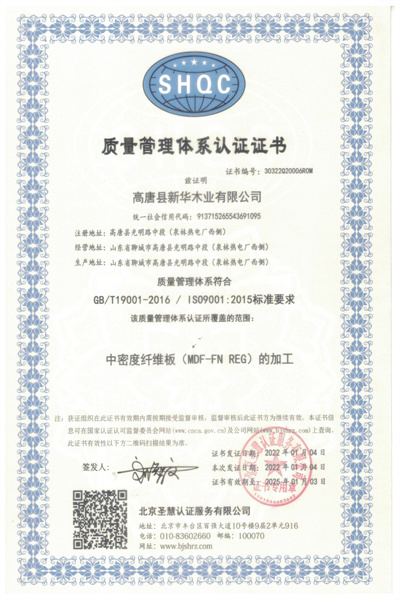

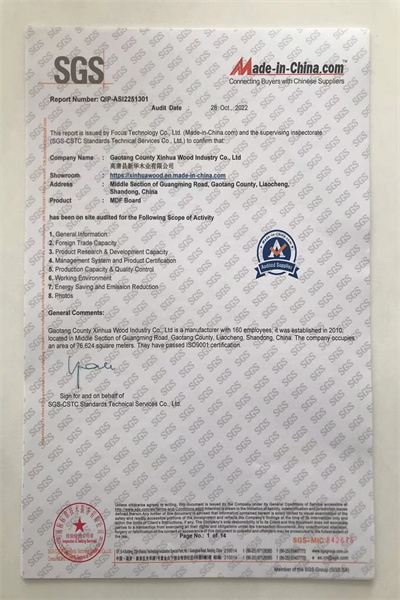

Products Certificates

Gaotang County Xinhua Wood Industry Co., Ltd. was established in 2010 . It covers an area of about 76,600 square meters.The company is located in Gaotang County, Liaocheng City,Shandong province, China. Our main products: Plain MDF, Plain HDF, Moisture Resistant MDF, Fire Resiatant MDF, Melamine Faced MDF, Film Faced MDF, PVC Coated MDF, UV Board ,PET Board, PETG Board, Wood Veneer Faced Board ,Chipboard, Particle Board, OSB2,OSB3,OSB4 etc. Product quality meet FSC ISO SGS standard. Our Products sells to more than 100 coutries and regions such as Japan, South Korea, the United States ,Africa, South America,India ,South-east Asia ect. Welcome your inquiry.