High Quality MDF for Construction

What are the customized machines for density board processing?

Sliding table saw is suitable for material cutting of density board, particle board, PVC board and other boards.

Edge banding machine is divided into automatic edge banding and semi-automatic edge banding machine, automatic edge banding machine is suitable for straight edge plate edge banding, semi-automatic edge banding machine is suitable for rounded and irregular plate edge banding.

The engraving machine is to process and carve MDF, particle board and other wood-based panels into various shapes according to the requirements of the drawings, and carve into various shapes according to the requirements to paste different color striped surfaces.

The veneer machine is divided into hot press and cold press. The hot press uses high temperature and high pressure technology to paste the impregnated paper on the surface of the density board. Upper facing paper, facing paper is divided into two types: manual sticking and roller sticking.

What details should be paid attention to when density board is veneered?

1. Moderate pressure: generally 2~3MPa, if it is too low, it will affect the bonding strength between the base material and impregnated paper, and if it is too high, it will damage the board.

2. Hot pressing time: it depends on the curing speed of the impregnated resin and the hot pressing temperature, generally 40-50s is appropriate. If the time is too long, the resin will be over-cured, lose its proper elasticity, and cause cracks in the subsequent processing. , warping, the time is too short, the resin is not cured enough, it is easy to produce sticking phenomenon, and affect the performance of the product surface and the durability of the product.

3. Processed base material: the surface of the board is flat, the sanding is uniform, and the moisture content is controlled at 6%~10%. The surface cannot be wetted well, resulting in cardboard delamination, and the density is controlled between 680 and 880.

4. Corresponding process: When the thin plate is hot pasted, if the board produced by the domestic production line can only be single pasted, it cannot be double pasted, otherwise it is easy to cause the phenomenon of board explosion. If the thin plate produced by the imported production line can be pasted Double stickers.

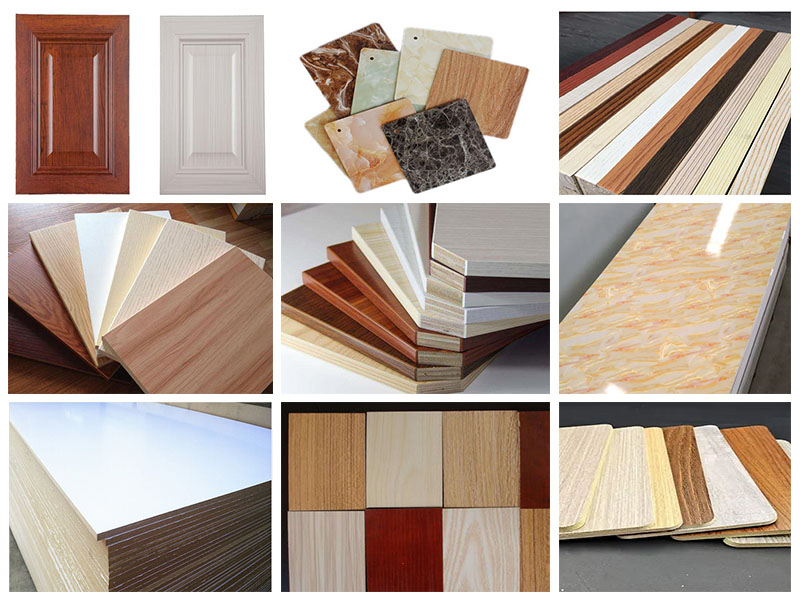

Different Finishes

Include solid color , wood grain color , marble stone color ,etc.

Xinhua Wood Factory Appearance

Xinhua Wood Factory Machinery

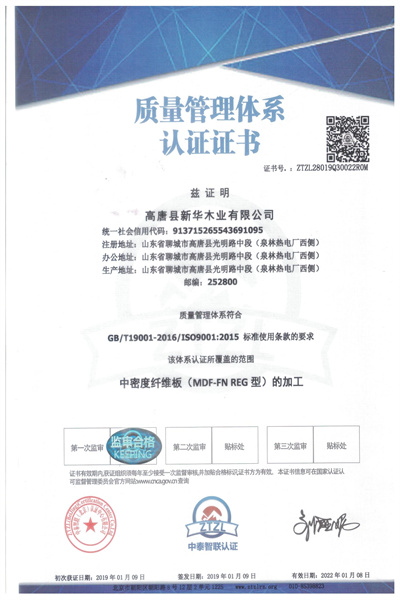

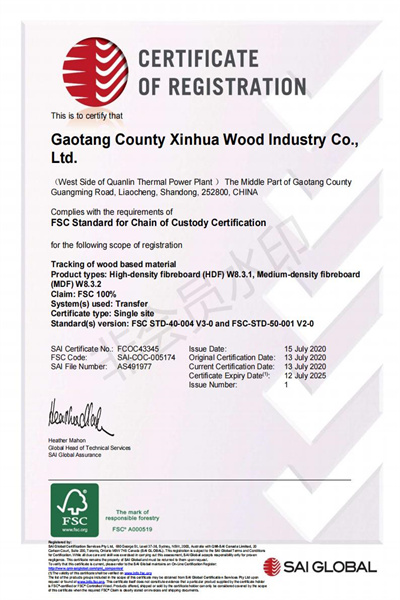

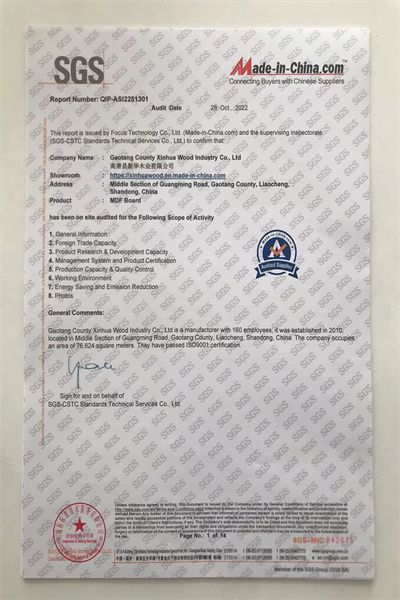

Xinhua Wood Products Quality Certificates

Xinhua Wood Factory Introduction

Gaotang County Xinhua Wood Industry Co., Ltd. was established in April 2010 with a registered capital of 11 million yuan. It covers an area of about 76,600 square meters, including a construction area of about 22,000 square meters. The company is located in Quanlin Ecological Park of Gaotang County Economic Development Zone, facing 105 National Road in the east, 308 National Road in the south, and Qingyin Expressway in the north. Our company is a professional enterprise integrating production, processing and sales of wood-based panels, with advanced production equipment and strong technical force. The company has more than 200 employees, including more than 50 senior technical managers. The leading products are 0.8-25mm medium and high density fiberboard, particle board .Oriented strand board ,fireproof board, moisture-proof board,etc., with an annual output of 500,000 cubic meters. The products are mainly sold to Hebei, Henan, Jiangsu, Shenyang, Sichuan and other 20 provinces. Our Products have passed ISO9001 quality system certification, FSC forest system certification and SGS international certification. Products are exported to Europe, America, Africa, the Middle East ,South-Asia,and other countries and regions. Xinhua Wood Industry warmly welcome people at home and abroad to visit and negotiate business!