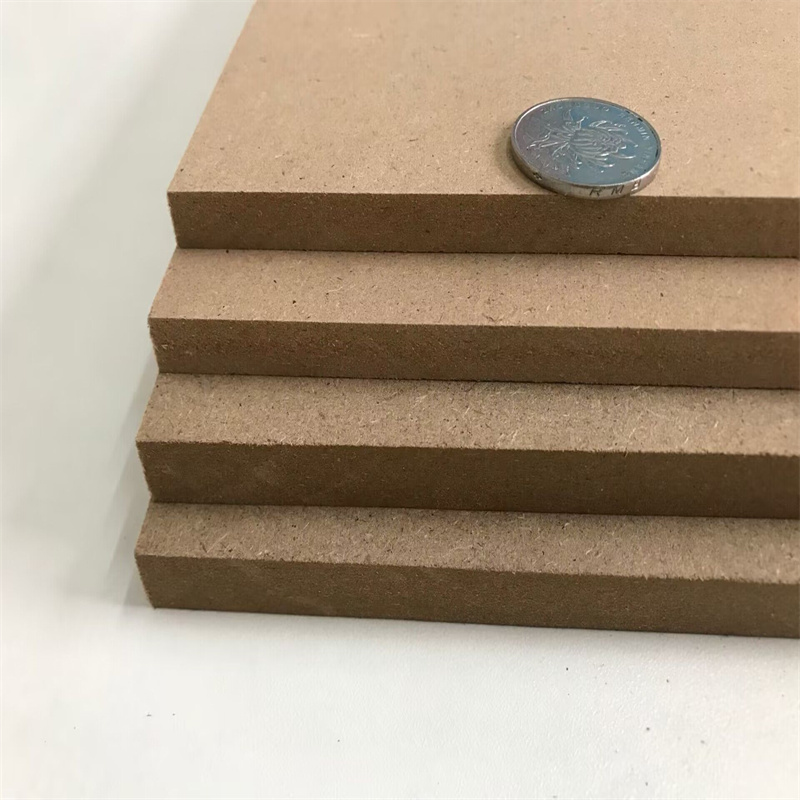

Factory Price MDF for Cabinet Cupboard

MDF Fiberboard Details

Product: | MDF |

Material: | Polar Pine Combi Hardwood |

Glue: | MDI WBP Phenolic E0 E1 E2 |

Size: | 1220*2440 1250*2500 mm or accept customization |

Thickness: | 1-25mm or accept customization |

MOQ: | 20 CBM |

Delivery time: | 15 days |

Thickness tolerance: | +-0.2mm |

Size Tolerance: | +-2mm |

Usage | Roof decking, furniture,packing,hoarding,signboards, portable building, constructional insolation board |

Shopping skills of MDF Fiberboard:

Environmental protection

According to national standards, MDF can be divided into E0, E1, and E2 according to its free formaldehyde content. The formaldehyde emission of E2 grade is ≤5mg/L; the formaldehyde emission of E1 grade is ≤1.5mg/L, which can be directly used for interior decoration; the formaldehyde emission of E0 grade is ≤0.5mg/L. When purchasing density boards, consumers should try to buy products with low formaldehyde emissions, which are safer.

Quality

Surface cleanliness: There should be no obvious particles on the surface of the density board with good surface cleanliness. Particles are caused by impurities brought in during the pressing process, which not only affects the appearance, but also makes the paint film easy to peel off.

Surface smoothness: when you touch the surface with your hands, it should feel smooth. If it feels astringent, it means that the processing is not in place.

Surface smoothness: The surface of the density board should be bright and smooth. If the surface is uneven from the side, it means that there is a problem with the material or coating process.

Overall flexibility: a harder board must be an inferior product.